Recently, Prof. Tu Chongqi's team from the Bone and Soft Tissue Tumor Center of West China Hospital has made another breakthrough in precision treatment, since it completed the world's first 3D-printed custom-made subtotal sacral supporter implantation.

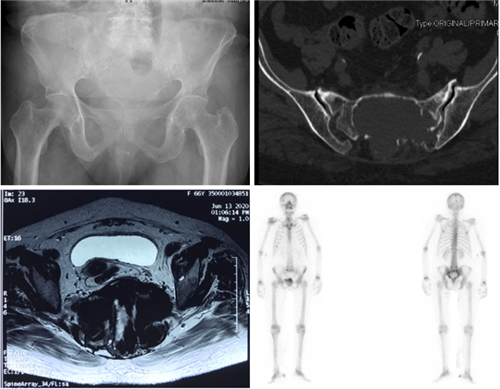

The patient was a 66-year-old woman, who felt lumbosacral pain without an obvious cause 10 months ago. Two months ago, besides the gradually increased pain, more symptoms such as walking weakness and incontinence of urine and feces appeared. The image fusion with CT and MRI revealed the tumor circled the sacral nerve in the form of "C"; en bloc resection of the tumor will cause total functional loss of the nerves below the first sacrum level. Thus, her living quality could be seriously affected by ambulation with crutches and incontinence of urine and feces. Meanwhile, the tumor invaded the greater part of the S1 vertebra, and the balance between en bloc tumor resection and the subsequent functional reconstruction must be a great challenge.

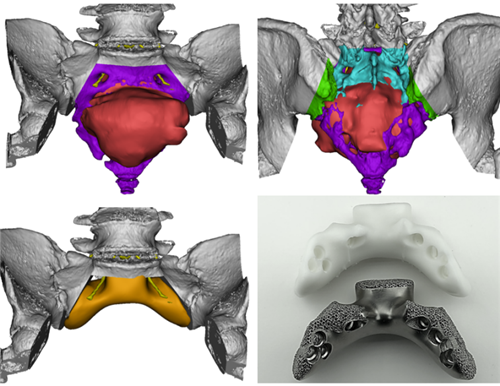

In this case, Prof. Tu Chongqi proposed the concept of "tumor-free area", based on which he adopted a step-by-step resection scheme. The spaces in the sacrum and the space between bone and nerve were flexibly used to complete the tumor exposure and neurolysis layer by layer. The whole process was tumor-free. Finally, the goals of en bloc tumor resection, the presacral retinaculum protection, and the main nerve roots preservation were achieved. During reconstruction, the implantation of 3D-printed custom-made endoprosthesis reestablished adequate stability of the anterior and posterior columns of the spine and avoided the fusion to the upper lumbar and the utilization of pedicle screws.

Since September 2013, Prof. Tu Chongqi's team has occupied a pioneering and leading position in the design method, biomechanical evaluation, and related surgical techniques of 3D-printed biological endoprosthesis after years of intensive research and practice. With the completion of the world's first "critical knee-preserving surgery in the tibia with 3D-printed custom-made titanium intercalary endoprosthesis " in October 2015, more than 150 cases with precision designed 3D-printed titanium endoprosthesis have been finished, involving the clavicle, humerus, radius, ulna, lumbosacral vertebra, hemipelvis, femur, patella, tibia, astragalus, and calcaneus. The related design philosophy and prosthesis have been widely accepted in more than 20 large general hospitals in China; and the research achievements have been repeatedly introduced at high-level academic conferences such as ISOLS, EMSOS, SICOT, CSCO, and COA, and received high praises from the academic community.